You encounter electric motors (E-Motors) everywhere in your daily life. From your car to your phone and even your toothbrush, E-Motors work to make your life easier, more efficient and more sustainable. While E-Motors range from tiny to immense, the Road to 2030 focuses on those used in mobility vehicles, ranging from cars and trucks to vehicles used in aviation and maritime applications.

As mobility sectors embrace electrification at a higher rate, investment in the technologies that power this shift becomes more critical. E-Motors are taking center stage, as the industry anticipates mass growth of their use in conjunction with propulsion batteries and increased stake in their innovation.

As a part of the Road to 2030 initiative, join us to examine how E-Motor usage will grow in the Detroit Region mobility ecosystem and beyond.

How It Works

In the mobility industry, E-Motors are used for the propulsion of electrified technologies, including light, medium and heavy automotive vehicles, as well as construction and mining vehicles, off-roading vehicles and aerospace and maritime technologies.

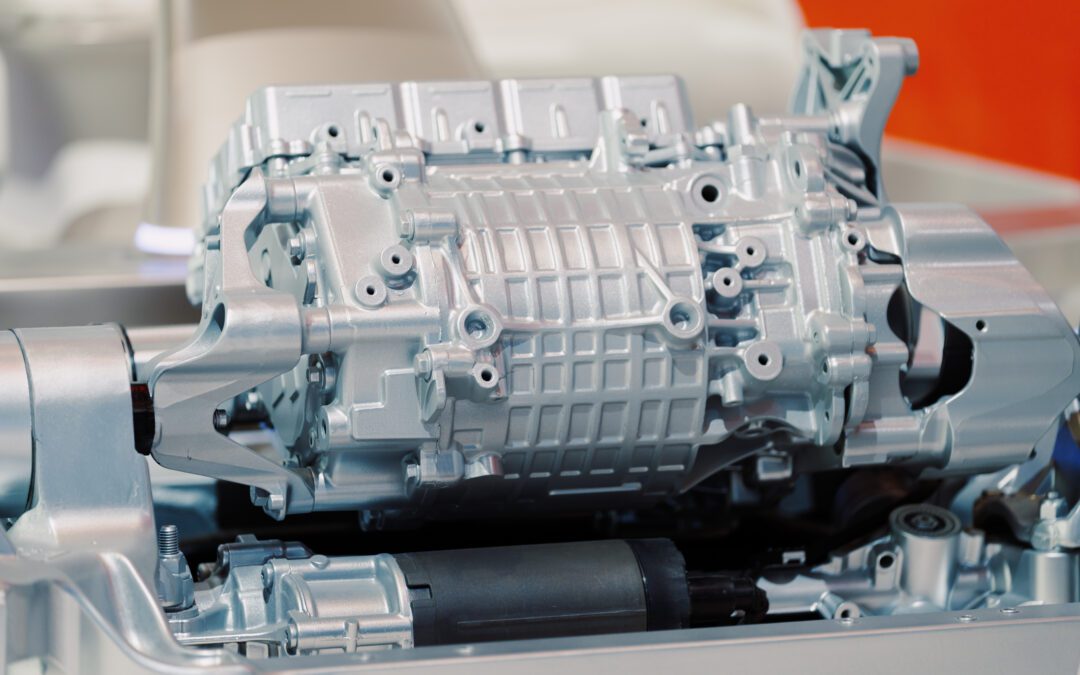

Electric motors in propulsion systems shift power from electricity within a propulsion battery to mechanical energy. There are magnetic fields inside the motor, shifting in the interaction of magnetic fields which convert the energy.

There are four key components that make up the motor, including a rotor, stator, bearings and control electronics. Rotors spin to transmit power, working alongside the stator, which is a fixed set of coils creating a magnetic field. The bearings help smooth out the rotation and reduce friction. Control electronics even out the voltage, frequency and current within the motor.

Types of electric motors primarily include AC motors and DC motors. AC motors are powered by alternating currents and are typically used in mid-to-high end EVs. DC motors are powered by direct currents and are used in mobility technologies like smaller electric cars, scooters, e-bikes and motorcycles.

Expansion Potential

Future innovation in electric motors hopes to enable motor design to be reusable or recyclable, allowing for heightened sustainability at the end of the technology’s life. Additionally, research into new materials, design and technologies for motor construction will enable further penetration and growth for e-motors across the mobility industry.

The impact of further innovation and wider adoption of electric and hybrid mobility technologies will enable continued growth for e-motor technologies. In the U.S., penetration of E-Motor technology for all U.S. mobility sectors is predicted to grow from 20.5% in 2024 to 61% in 2030.

In Michigan, organizations like the Office of Future Mobility and Electrification, the Electrification Coalition, the University of Michigan College of Engineering Electric Vehicle Center (EVC) and other initiatives influence the continuation of innovation in the EV industry. The Office of Future Mobility and Electrification partners with GEM to connect mobility innovators with testing and proving services.

The EVC, funded by a $130 million investment from the Department of Labor and Economic Opportunity (LEO), a GEM partner, aims “to make Michigan the E-Motor Capital.” The EVC supports this goal through four main pillars:

- Technology & Innovation

- Education

- Workforce Development

- Facilities Expansion

Having supportive infrastructure for E-Motor development and testing creates space for growth in the region and, in turn, electric mobility technologies. This is especially clear for light vehicles, which include e-bikes, e-scooters and small automobiles.

In Michigan, E-Motor production for light vehicles is predicted to grow from under 100,000 units in 2024 to 14.1 million units by 2030, an increase of more than 1,200%.

Despite these forecasts, there are still challenges when looking toward the widespread integration of E-Motor technologies:

- Integration of new E-Motor systems into complex technologies

- Finding new materials to improve cost, durability, sustainability and availability

- Meeting and exceeding regulatory requirements as organizations look to innovate and integrate E-Motor technology

Use Cases

There are many companies in the Detroit Region mobility ecosystem that work in electric motors. They range from multiple automakers to suppliers (such as Bosch, Continental, Scheaffler, and many others), to startup companies. A few examples are highlighted below:

- Reuland Electric Motors is a manufacturer of electric motors for mobility sectors and beyond. With a manufacturing location in Howell, Reuland develops custom motors to meet the needs of clients on the path of electrification.

- Ford Van Dyke Electric Powertrain Center, based in Sterling Heights, focuses on the creation of electric motors and axles for hybrid and electric vehicles, supporting Ford’s electric energy goals.

- Detroit Engineered Products (DEP), based in Troy, works in the design of e-motor systems to improve various aspects of motor systems and assist programs in facing the challenges of E-Motor integration.

As E-Motor innovation grows to match the increasing demand for electric mobility technologies, GEM and its partners work to expand the ecosystem and continue to drive mobility business to the Detroit Region. To accomplish this goal, GEM creates and fosters connections between organizations to provide testing support, train local talent, support entrepreneurs and startups, create and transform supply chain systems for manufacturers and find sites for projects in the 11-county mobility region. We have the resources to support innovators effectively and enable the development of business in the Detroit mobility region.

Go to DetroitRegionalPartnership.com

Go to DetroitRegionalPartnership.com